Product Description

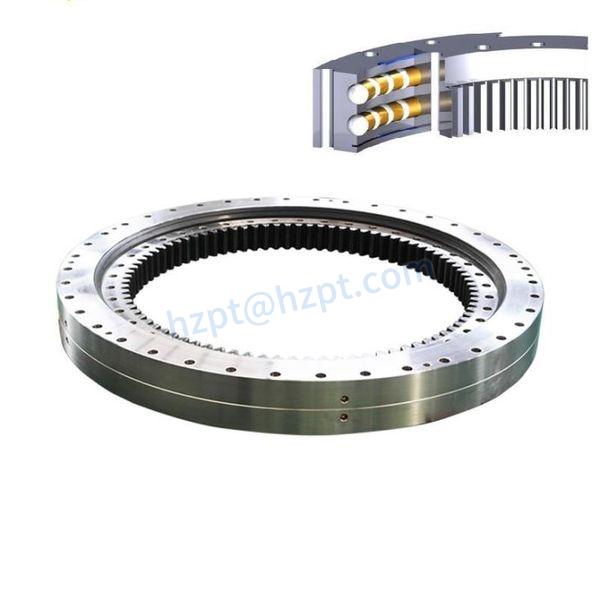

1. Product Description

| Material | 42CrMo or 50Mn | ||

| Delivery Time | 15 Days | ||

| Transport | By sea, by air, by railway, by express | ||

| Warranty Period | 18 Months | ||

| Package | Wooden Box | ||

| Payment | T/T , Western Union, Paypal | ||

2. Product show

3. Company profile

HangZhou King Slewing Bearing Technology Co., Ltd. is a specialized manufacturer and exporter for excavator and crane slewing bearings. The company occupies the workshop area of 6,

6. Our machine tools

7. Packaging by wooden box

8. Transportation way: By sea/ air/ rail/ road/ TNT/DHL/UPS/Fedex,ect.

9. Contact information

Company: HangZhou King Slewing Bearing Technology Co.,Ltd

Address: CZPT Xinzhan CZPT Science and Technology Park, Xinzhan District, HangZhou, ZheJiang Province

Contact person: Amy Sun

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed |

| Rolling-Element Number: | 50mn/42CrMo |

| Roller Type: | Straight Raceway |

| Material: | Alloy |

| Type: | Internal Gear |

| Samples: |

US$ 1000/Set

1 Set(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Are there any Specific Design Considerations when Using Slewing Bearings in Heavy-Duty Applications?

When utilizing slewing bearings in heavy-duty applications, several specific design considerations are essential to ensure reliable performance, safety, and longevity. Here are key factors to keep in mind:

- Bearing Selection:

Choose slewing bearings with higher load-carrying capacities that are specifically designed for heavy loads. Opt for designs that distribute loads evenly and minimize stress concentrations.

- Load Distribution:

Heavy-duty applications often involve uneven load distribution due to various operational conditions. Bearing designs should account for these variations to prevent premature wear and failure.

- Material Selection:

Select materials that can withstand heavy loads, shock loads, and potential impacts without deformation or fatigue. High-strength steels and advanced materials with excellent mechanical properties are often preferred.

- Rolling Element Size and Quantity:

Increase the size and quantity of rolling elements to distribute heavy loads more effectively. Larger and more rolling elements can handle higher forces while reducing stress on individual elements.

- Lubrication and Sealing:

Heavy-duty applications generate more heat and friction. Use appropriate lubrication methods and consider advanced sealing solutions to ensure proper lubricant retention and prevent contamination.

- Mounting and Alignment:

Ensure accurate mounting and alignment to prevent unnecessary stress on the bearing components. Misalignment can lead to premature wear and reduced bearing life.

- Structural Integration:

Integrate the slewing bearing into the overall machine design, considering factors like structural support, load paths, and interfaces with other components.

- Dynamic Loading:

Heavy-duty applications often involve dynamic loading scenarios. Consider factors such as impact loads, acceleration, and deceleration when designing the bearing and its supports.

- Heat Dissipation:

Heavy loads and continuous operation can generate heat. Design the bearing housing and cooling systems to dissipate heat effectively and prevent overheating.

- Maintenance Access:

Design the bearing arrangement to allow for convenient maintenance and inspections. Access to lubrication points, seals, and other components should be easy to facilitate regular upkeep.

- Load Surges and Shock Absorption:

Heavy-duty applications might experience sudden load surges or impacts. Incorporate shock-absorbing mechanisms or dampers to protect the bearing from excessive forces.

In summary, heavy-duty applications demand careful consideration of bearing selection, materials, load distribution, lubrication, and other design elements to ensure the reliable and durable performance of slewing bearings under substantial loads.

Are there any Specific Safety Precautions to Take When Working with Slewing Bearings?

Working with slewing bearings involves certain safety considerations to prevent accidents and ensure the well-being of personnel. Here are some specific safety precautions to take:

- Training and Knowledge:

Ensure that personnel working with slewing bearings are properly trained and have a clear understanding of the equipment, procedures, and safety protocols.

- Protective Equipment:

Use appropriate personal protective equipment (PPE), including gloves, safety goggles, and hearing protection, to safeguard against potential hazards.

- Lockout/Tagout:

Follow lockout/tagout procedures when performing maintenance or repairs. Locking out equipment prevents unexpected activation and potential hazards.

- Machine Shutdown:

Before working on machinery containing slewing bearings, ensure that the equipment is properly shut down, power sources are disconnected, and any stored energy is released.

- Proper Tools:

Use suitable tools and equipment for maintenance and assembly to prevent accidents and ensure accurate work.

- Weight Handling:

If handling heavy slewing bearing components, use appropriate lifting equipment and techniques to avoid strain or injury.

- Secure Work Area:

Ensure that the work area is clean, organized, and free from obstacles. This reduces the risk of tripping hazards and improves overall safety.

- Work with a Partner:

Whenever possible, perform tasks involving slewing bearings with a partner. Having someone nearby can provide assistance in case of emergencies.

- Safe Access:

Ensure safe access to the work area, including the use of stable platforms or ladders, to prevent falls or slips.

- Warning Signs:

Use proper warning signs and labels to alert others about ongoing maintenance or potential hazards related to slewing bearings.

- Manufacturer Guidelines:

Adhere to the manufacturer’s recommendations for maintenance, lubrication, and safety practices specific to the slewing bearings being worked on.

- Emergency Procedures:

Have clear emergency procedures in place and communicate them to all personnel. Know the location of emergency equipment and exits.

By following these safety precautions, you can minimize risks associated with working on slewing bearings and create a safer environment for maintenance personnel.

What is a Slewing Bearing and How Does It Work?

A slewing bearing, also known as a turntable bearing, is a specialized type of rolling-element bearing designed to handle axial, radial, and moment loads simultaneously. It allows rotational movement between two parts while supporting the loads applied to them. Slewing bearings are commonly used in various applications such as cranes, construction equipment, wind turbines, and industrial machinery.

At its core, a slewing bearing consists of multiple components, including an outer ring, an inner ring, rolling elements (balls or rollers), and in some designs, a gear or teeth arrangement. The outer ring is typically stationary and mounted to a fixed structure, while the inner ring is connected to the rotating part. The rolling elements provide smooth movement between the two rings, enabling rotation.

Slewing bearings work by minimizing friction and distributing loads effectively across the rolling elements. When a rotational force is applied to the inner ring, the rolling elements facilitate the smooth rotation of the inner ring relative to the outer ring. The rolling elements are positioned within raceways or grooves in the rings, ensuring proper contact and load distribution.

The addition of gears or teeth to the slewing bearing design enables the transmission of torque between the inner and outer rings. This feature is particularly useful when precise rotation control is required, as seen in applications like cranes and heavy machinery.

In summary, a slewing bearing functions as a rotational joint that can support various loads and movements. Its design, which includes rolling elements and optional gear systems, allows it to manage axial, radial, and moment loads while facilitating smooth rotation between connected parts.

editor by CX 2024-03-04

by

Tags:

Leave a Reply