Product Description

china slewing ring bearing swing bearing RKS.161.16.1424 slew ring bearing for wind driven generator

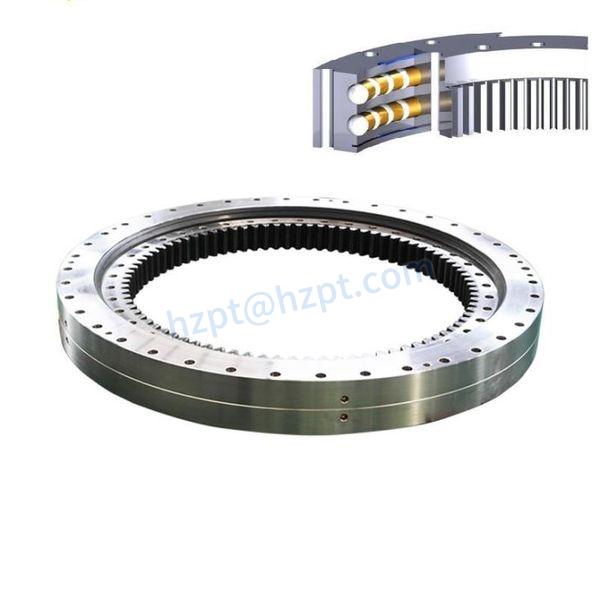

Four-point contact ball slewing turntable bearings

consist of 2 ring seats. Compact structure, light weight, steel ball and arc track contact at 4 points, can bear axial force, radial force and overturning moment at the same time, has strong dynamic load.

Single row cross roller slewing bearing

Composed of 2 or 3 rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and precesion products.

Double row ball slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Three row roller slewing bearing

Three row roller bearing CZPT to bear all kinds of loads at the same time, it is the largest 1 of the 4 structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

product-list-1.html

| Type | • Single row 4 point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | HangZhou ZheJiang |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Process

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Straight Raceway |

| Material: | 50mn/42CrMo |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do Environmental Factors such as Temperature and Exposure to Corrosive Substances Impact Slewing Bearings?

Environmental factors, including temperature variations and exposure to corrosive substances, have a significant impact on the performance and longevity of slewing bearings. Here’s how these factors affect slewing bearings:

- Temperature Extremes:

High Temperatures: Excessive heat can lead to premature bearing failure by affecting the lubrication properties, causing thermal expansion, and accelerating wear. Bearings operating at high temperatures require special lubricants and materials that can withstand thermal stresses.

Low Temperatures: Extremely low temperatures can lead to reduced lubricant viscosity, increasing friction and wear. Bearings operating in cold environments might require low-temperature lubricants and materials that maintain their properties in freezing conditions.

- Corrosive Substances:

Moisture and Water: Exposure to moisture and water can lead to rust, corrosion, and erosion of bearing components. This is particularly relevant in marine environments or applications exposed to frequent wet conditions.

Chemical Exposure: Corrosive chemicals and aggressive substances can deteriorate bearing materials and lubricants, leading to accelerated wear and potential structural damage.

Dust and Particles: Dust, dirt, and particles can infiltrate the bearing, causing abrasive wear and increasing the risk of damage to the rolling elements and raceways.

- Effects on Lubrication:

Temperature extremes and exposure to corrosive substances can compromise the effectiveness of lubrication. High temperatures can degrade lubricants, while corrosive environments can contaminate or dilute lubricants, reducing their protective qualities.

- Material Selection:

When designing slewing bearings for specific environments, choosing appropriate materials is crucial. Stainless steels, specialized coatings, and corrosion-resistant materials are often preferred for applications where corrosion is a concern.

- Sealing Solutions:

Effective sealing solutions are essential to protect slewing bearings from moisture, chemicals, and contaminants. Proper sealing helps maintain lubrication integrity and prevents external substances from entering the bearing.

- Maintenance and Inspection:

Regular maintenance and inspections are critical in environments with temperature fluctuations and corrosive exposure. Prompt removal of contaminants, re-lubrication, and replacement of damaged parts can mitigate the effects of these factors.

- Application-Specific Considerations:

Understanding the environmental conditions of the application is essential for selecting the appropriate slewing bearing type, materials, and maintenance practices. Customized solutions might be necessary for extreme environments.

In summary, temperature variations and exposure to corrosive substances can degrade the performance and durability of slewing bearings. Proper material selection, sealing, lubrication, and maintenance practices are vital for ensuring the bearings’ reliability in challenging environmental conditions.

How does Preload Affect the Performance and Stability of Slewing Bearings?

Preload is a critical factor that can significantly impact the performance and stability of slewing bearings. It involves applying a controlled axial force to the bearing components before assembly. Here’s how preload affects slewing bearings:

- Reduced Internal Clearance:

Applying preload reduces the internal clearance between the rolling elements and raceways. This minimizes play or clearance in the bearing, enhancing its rigidity and reducing the potential for rolling element skidding during operation.

- Improved Stiffness:

Preloaded slewing bearings exhibit higher stiffness due to the elimination of internal clearance. This improved stiffness is crucial in applications requiring precise positioning, such as robotics and high-precision machinery.

- Enhanced Load Distribution:

Preload improves the load distribution among rolling elements, minimizing stress concentrations and promoting uniform load sharing. This is especially important in applications with varying loads and forces.

- Reduced Vibrations:

By eliminating internal clearance and minimizing rolling element movements, preloaded bearings experience reduced vibrations during operation. This contributes to smoother and more stable equipment performance.

- Precise Positioning:

Preload ensures minimal movement within the bearing during rotational changes, making it suitable for applications where precise positioning and accurate motion control are essential.

- Resistance to External Loads:

Preloaded bearings are better equipped to handle external forces and shocks without significant deformation or misalignment, maintaining consistent performance even under varying conditions.

- Reduced Wear:

With reduced internal clearance and controlled movement, preloaded bearings experience less wear and fatigue. This extends their service life and reduces the frequency of maintenance.

- Limitations:

However, excessive preload can lead to increased friction, heat generation, and potential damage. It’s essential to apply the right amount of preload according to manufacturer recommendations and application requirements.

In summary, preload in slewing bearings enhances rigidity, load distribution, and stability, making them suitable for applications that demand precise movement and control. Properly applied preload ensures optimal performance and extends the operational life of the bearing.

What are the Main Applications of Slewing Bearings?

Slewing bearings find wide applications across various industries due to their ability to handle complex loads and facilitate rotational movement. Some of the main applications of slewing bearings include:

- Construction Machinery: Slewing bearings are essential components in construction equipment such as excavators, cranes, concrete pumps, and drilling rigs. They enable smooth rotation and movement, supporting heavy loads and dynamic forces.

- Wind Turbines: In wind energy systems, slewing bearings are used to orient the rotor blades and nacelle to capture maximum wind energy. Their durability and load-bearing capacity make them crucial for efficient wind turbine operation.

- Mining Equipment: Slewing bearings are used in mining machinery like stacker-reclaimers and conveyor systems. They enable the movement of large loads, contributing to efficient material handling and processing.

- Marine Applications: Slewing bearings are employed in ship cranes, davits, and other marine equipment. They assist in cargo handling, ship maintenance, and various onboard operations.

- Aerial Work Platforms: Slewing bearings are integral to aerial platforms and access equipment. They enable controlled and safe movement for workers at elevated heights.

- Robotics and Automation: Slewing bearings play a role in industrial robots and automation systems. They facilitate precise and controlled rotational movement in manufacturing processes.

- Medical Equipment: Some medical imaging equipment, such as CT scanners and MRI machines, use slewing bearings for rotational movement, contributing to accurate diagnostics.

- Defence and Aerospace: Slewing bearings are employed in defense equipment like radar systems and missile launchers, as well as in aerospace applications like aircraft landing gear.

These are just a few examples of the many applications of slewing bearings across different industries. Their ability to handle diverse loads and rotational movements makes them versatile components in various machinery and equipment.

editor by CX 2024-04-08

Leave a Reply