Product Description

Excavator slewing circle,turnable circle,swing circle for Kobelco,JCB,Doosan,Komatsu tractor

Good quality and Best services at reasonable prices

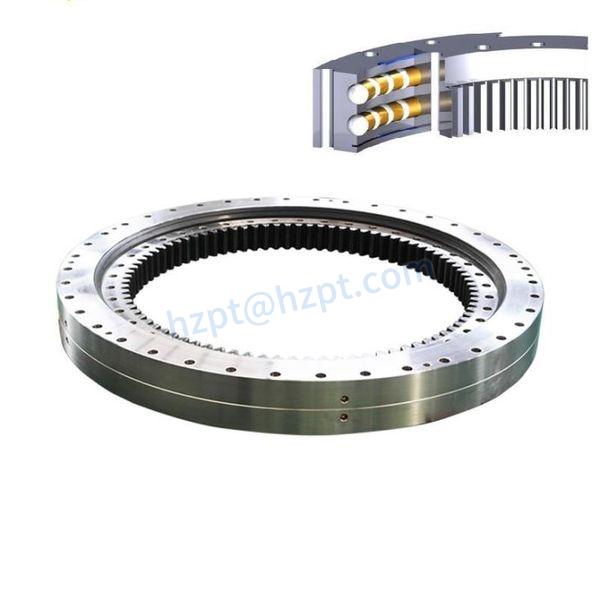

Slewing Bearing

Material: 50Mn

Technology: Forging or Casting

Finish: Smooth

Hardness: HRC50-60

Deepth: 4mm-10mm

Heat treatment: Quenching

Dimensions: International Standard

Port: HangZhou

Supply Ability: 100000 Piece/Pieces per Month can improve

Packaging Detail: Wooden case/pallet

Delivery Detail: 10-20 days after the payment

Certificate: ISO9002

Warranty time: 12 months

Service: OEM and after-sale service

Our manufacturer can supply the Model below:

Komatsu:

PC40-7 PC60-5-6-7 PC75 PC100-3-5 PC120-5 PC130 PC200-2-3-4-5-6-7-8 PC220-1-3-5 PC230 PC240 PC300-1-5-6-7 PC400-1-3-5

Hitachi:

EX40 EX55 ZX55 EX55-5B EX60-2-3 EX70(ZX70) EX100M EX100-1-2-3-5 EX120 EX150 EX160 EX200-1-2-3-5 ZX200 ZX210 EX220 ZX230 EX300-1-2-3-5 EX330 EX400 UH08 UH07 UH10 UH14

Sumitomo:

SH60 SH65 SH100 SH120-A3 SH120 SH200 SH220-1-5 SH260 SH280 SH300-1-2-3 SH340 SH580-5 S25 S35 S120 S160 S250 S260 S265F2 S280 S280F2 S280FA

Kobelco:

SK30 SK40 SK60 SK100 SK120 SK200-1-6 SK220-1-3 SK230-3-6 SK300 SK320 SK07-1-2-7 SK07N2 SK09

Caterpillar:

E70 E110 E120B E180 E200B E240 E300B E307 CAT311 CAT312 E320 E325 E330 E450 MS180

Daewoo:

DH55 DH60 DH70 DH80 DH150 DH150W DH175 DH200 DH210 DH215-7-9 DH220-3-5-7 DH225 DH255 DH258 DH280 DH300 DH320 DH330 DH340 DH370 DH400

Kato:

HD250 HD250SE HD400 HD450 HD500 HD510 HD550 HD550SE HD650 HD700 HD770 HD800 HD1250 HD1430

Hyundai:

R55 R60-5-7-9 R80 R110 R130-1-2-7 R150 R190 R200-1-2 R210 R215 R220 R225-7 R265 R290 R305 R455

Volvo:

EC55B EC60C EC140B EC200B EC210B EC240B EC290B EC360B EC460B EC550

Bulldozer:

D20 D31 D50 D60 D65 D30 D40 D60-3 D6B D5 D80 D85 D3C D4C D4D D75 D80A-7 D4E D4H-1 D31-15 D31-18 D50-15 D50-16 D6D D5H D8N D9N D155 D31 D355 D10

China tractor undercarriage parts for JCB,Komatsu,Doosan,Liebherr

HangZhou Fortune Machinery Co., Ltd. is 1 of main manufacturers and exporters of undercarriage parts for excavators and bulldozers for more than 10 years in China. Its factory is located at HangZhou City of ZheJiang Province, very near HangZhou Port with a very convenient transportation.

HangZhou Fortune Machinery mainly supply undercarriage replacement parts such as track rollers, top rollers, sprockets, segments, idler assy, track link assy, track shoe, bucket, bucket teeth, bucket link, I link, cutting side, end bits, bushings pins, bolts and nuts for excavators and bulldozers. Its products are applicable for most famous makes such as Komatsu, Hitachi, Caterpillar, Kobelco, Kato, Daewoo, Hyundai, CZPT and so on. Most products are exported to European, Southeast Asia, Middle East, South America etc.

With the principal “Good quality and Best services at reasonable prices”, we strive to continually improve our production technique to provide better products at better prices. We cordially welcome the customers from all over the world to consult and visit, on the basis of mutual benefit and creat refulgence together.

| BRAND | ||||||||

| KOMATSU | PC30 | PC40 | PC45 | PC60 | PC75 | PC100 | PC120 | PC200 |

| EXCAVATOR | PC220 | PC300 | PC350 | PC400 | ||||

| CATERPILLAR | E70B | E110 | E120 | E200B | E307 | E311 | E312 | E320 |

| EXCAVATOR | E322 | E325 | E300B | E330 | ||||

| KOMATSU | D20 | D21 | D30 | D31 | D37 | D40 | D50 | D60 |

| BULLDOZER | D63 | D65 | D80 | D85 | D135 | D155 | D355 | D375 |

| CATERPILLAR | D3C | D3D | D4 | D4C | D4D | D4E | D5 | D5H |

| BULLDOZER | D6 | D6C | D6D | D6H | D7E | D7G | D8N | D9N |

| HITACHI | EX30 | EX40 | EX60 | EX100 | EX120 | EX200 | EX220 | EX300 |

| EX400 | ZAX200 | ZX330 | ZX350 | UH07 | UH081 | UH083 | ||

| DAEWOO | DH55 | DH200 | DH220 | DH280 | DH300 | DH320 | ||

| HYUNDAI | R55 | R110 | R130 | R150 | R200 | R210 | R250 | R290 |

| KEBELCO | SK60 | SK100 | SK120 | SK200 | SK220 | SK300 | K904 | K907 |

| MITSUBISHI | MS110 | MS120 | MS140 | MS180 | ||||

| KATO | HD140 | HD250 | HD400 | HD550 | HD700 | HD850 | HD900 | HD1220 |

| SAMSUNG H.I. | MX8 | SE200 | SE210 | SE280 | MX292 | SE350 | ||

| SUMITOMO | SH70 | SH100 | SH120 | SH160 | SH200 | SH280 | SH300 | SH340 |

Contact us:

HangZhou Fortune Machinery Co., Ltd.

Contact person:James

fortunepart

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| After-sales Service: | One Year |

|---|---|

| Warranty: | One Year |

| Type: | Crawler |

| Application: | Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

What is the Typical Lifespan of Slewing Bearings under Different Operating Conditions?

The lifespan of slewing bearings can vary based on different operating conditions and factors that influence wear and fatigue. Here’s a general overview of the typical lifespan under various scenarios:

- Light Loads and Proper Lubrication:

When operating under light axial, radial, and moment loads and with consistent and proper lubrication, slewing bearings can often exceed 20,000 to 30,000 hours of service life.

- Heavy Loads and Harsh Environments:

In heavy-duty applications where the bearings handle substantial loads, such as construction equipment or mining machinery, the lifespan might range from 10,000 to 20,000 hours. Harsh environments with dust, moisture, and corrosive substances can affect the bearing’s durability.

- Corrosive Environments:

In environments with high levels of corrosion, such as marine applications, the lifespan of slewing bearings might be reduced due to the impact of corrosive elements on the bearing’s materials.

- High-Speed Applications:

In applications requiring high rotational speeds, such as certain automation systems or machinery, the bearing’s lifespan might be affected due to increased friction and wear associated with higher speeds.

- Poor Lubrication and Maintenance:

If proper lubrication and maintenance practices are neglected, the bearing’s lifespan can be significantly shortened. Insufficient lubrication leads to increased friction and wear, potentially reducing the lifespan by a considerable margin.

- Shock and Impact Loads:

Applications subject to frequent shock and impact loads, like certain material handling equipment, can experience premature wear and fatigue, leading to a reduced lifespan.

- Temperature Extremes:

Operating in extreme temperatures, whether high or low, can affect the performance of slewing bearings and potentially reduce their lifespan due to changes in material properties and lubrication effectiveness.

- Customization and Quality:

The quality of the bearing, manufacturing processes, and the extent of customization also play a role. High-quality bearings designed for specific applications might offer longer lifespans.

- Manufacturer’s Recommendations:

Always refer to the manufacturer’s guidelines and recommendations for the specific slewing bearing model. They provide valuable insights into maintenance intervals, lubrication, and expected service life.

It’s important to note that these are general estimates, and actual lifespans can vary depending on numerous factors. Regular maintenance, proper lubrication, adherence to guidelines, and consideration of operating conditions are essential for maximizing the lifespan of slewing bearings.

Are there any Specific Safety Precautions to Take When Working with Slewing Bearings?

Working with slewing bearings involves certain safety considerations to prevent accidents and ensure the well-being of personnel. Here are some specific safety precautions to take:

- Training and Knowledge:

Ensure that personnel working with slewing bearings are properly trained and have a clear understanding of the equipment, procedures, and safety protocols.

- Protective Equipment:

Use appropriate personal protective equipment (PPE), including gloves, safety goggles, and hearing protection, to safeguard against potential hazards.

- Lockout/Tagout:

Follow lockout/tagout procedures when performing maintenance or repairs. Locking out equipment prevents unexpected activation and potential hazards.

- Machine Shutdown:

Before working on machinery containing slewing bearings, ensure that the equipment is properly shut down, power sources are disconnected, and any stored energy is released.

- Proper Tools:

Use suitable tools and equipment for maintenance and assembly to prevent accidents and ensure accurate work.

- Weight Handling:

If handling heavy slewing bearing components, use appropriate lifting equipment and techniques to avoid strain or injury.

- Secure Work Area:

Ensure that the work area is clean, organized, and free from obstacles. This reduces the risk of tripping hazards and improves overall safety.

- Work with a Partner:

Whenever possible, perform tasks involving slewing bearings with a partner. Having someone nearby can provide assistance in case of emergencies.

- Safe Access:

Ensure safe access to the work area, including the use of stable platforms or ladders, to prevent falls or slips.

- Warning Signs:

Use proper warning signs and labels to alert others about ongoing maintenance or potential hazards related to slewing bearings.

- Manufacturer Guidelines:

Adhere to the manufacturer’s recommendations for maintenance, lubrication, and safety practices specific to the slewing bearings being worked on.

- Emergency Procedures:

Have clear emergency procedures in place and communicate them to all personnel. Know the location of emergency equipment and exits.

By following these safety precautions, you can minimize risks associated with working on slewing bearings and create a safer environment for maintenance personnel.

How do Different Types of Slewing Bearings Vary in Terms of Design and Function?

Different types of slewing bearings vary significantly in terms of their design and function, catering to diverse industrial requirements. Some common variations include:

- Single-Row Ball Slewing Bearings: These bearings consist of a single row of balls positioned between two rings. They are compact and suitable for light to moderate axial and radial loads, making them useful in applications like small cranes and excavators.

- Double-Row Ball Slewing Bearings: These bearings have two rows of balls and higher load-carrying capacity compared to single-row types. They find use in applications requiring higher loads and moment resistance, such as larger cranes and construction machinery.

- Three-Row Roller Slewing Bearings: These bearings use cylindrical rollers to handle heavy axial, radial, and moment loads. They are commonly found in heavy-duty applications like harbor cranes and mining equipment.

- Cross Roller Slewing Bearings: These bearings have cylindrical rollers arranged in a crossed pattern between the inner and outer rings. They offer high stiffness and precision, making them suitable for applications like robotic arms and precision machinery.

- Wire Race Slewing Bearings: These innovative bearings use a thin wire race to support the rolling elements. They are lightweight and compact, often used in medical equipment and aerospace applications.

- Ball-And-Roller Combination Slewing Bearings: These hybrid bearings combine ball and roller elements to achieve a balance between load capacity and precision. They find use in various industrial machines and equipment.

- Gearless Slewing Bearings: In some applications, slewing bearings incorporate no gears or teeth. They are used where external gear reduction is present or precise rotation isn’t required.

- Geared Slewing Bearings: These bearings include internal gears or teeth that allow torque transmission between the inner and outer rings. They are essential in applications requiring controlled rotation, such as cranes and wind turbines.

The choice of slewing bearing type depends on factors like load requirements, available space, rotational precision, and the specific industrial application. Understanding the variations helps engineers select the most suitable bearing for optimal performance.

editor by CX 2024-04-09

Leave a Reply