Product Description

Product Description

Item No.: SS6305-2RS

Type: Deep Groove Ball Bearing

Material: Stainless Steel(AISI440C/9Cr18)

Bore diameter: 25mm Outer diameter : 62mm Width(Height/Thickness): 17mm

Size: 25*62*17mm

Dynamic load C0: 21.2 Static load C0r: 10.9 Grease: 12000 Oil: 14000

Cage(retainer): Ribbon Cage(SPCC/T8)

Closures: 2 Rubber Seals(NBR)

Balls: Stainless Steel Balls

Lubrication: Grease

| Item No. | Bore diameter (mm) |

Outer diameter (mm) |

Width(Height/Thickness) (mm) |

Closures |

| SS6305-2RS | 25 | 62 | 17 | 2 Rubber Seals(NBR) |

Detailed Photos

SS6305-2RS

Our Advantages

Compared with ordinary bearings, stainless steel bearings have distinct material advantage because stainless steel bearings

have more wide application than ordinary bearings. In rusty and corrosive environment, the cost performance of stainless steel

bearings is outstanding specially.

Stainless Steel Bearing:

1. stronger anti-rust property and anti-corrosion property.

2. CZPT to serve under -60ºC~+300ºC.

3. resist humidity and corrosion caused by other media.

4. has a deep bearing raceway groove, and the fit between the bearing raceway and the ball is extremely high.

5. high mechanical strength and large loading capacity.

Our company provides high-precision homemade bearing of ordinary material, including deep groove ball bearing and full complement cylindrical roller bearings.

The material refers to high-quality bearing steel, thermal treatment technology is put under strict control, and it is CZPT to carry out cryogenic treatment. And full complement cylindrical roller bearings adopts advanced roller CZPT for thermal treatment. Other technologies are all processed by full-automatic and semiautomatic equipment, and the production technology and quality control are arranged as per P5 precision. It products widely support home and abroad manufacturers of electric tools, mechanical equipment, automobile components, etc.

Manufacture Equipment

Company Profile

HangZhou WOLEE INDUSTRIAL CO.,LTD

HangZhou WOLEE induststial Co., Ltd. was founded in 2015. It is a professional company which engages in import and export of industrial components and is a professional production base with joint stocks.

The company mainly operates bearings and other industrial components such as chain, CZPT rail, gear and micro gearbox. Its products are widely used in the fields of metallurgy, mining, papermaking, petrochemical, power, railway, aviation, cement, textile, machinery, etc., it has lots of clients among these fields and has accumulated rich experience to meet different demands of all sectors. At present, its trade scale expands increasingly, its clients are all across the world, and it wins the trust of home and abroad clients by virtue of good reputation.

The company adheres to the tenet of “people first, quality first, credit first and reputation first” and provides each client with top service.

It heartily hopes to join hands with you to create a wonderful world.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Non-Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

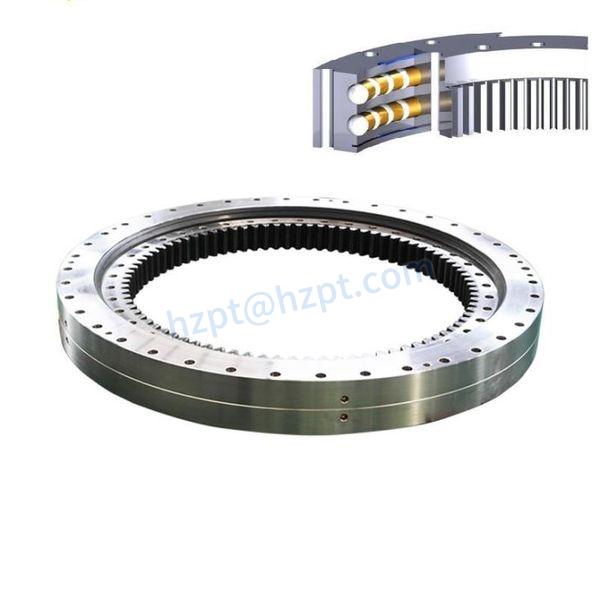

What Role do Seals and Enclosures Play in Protecting Slewing Bearings from Contaminants?

Seals and enclosures play a crucial role in safeguarding slewing bearings from contaminants, moisture, and other external factors that can lead to premature wear and damage. Here’s how seals and enclosures contribute to the protection of slewing bearings:

- Contaminant Exclusion:

Seals and enclosures create a physical barrier that prevents contaminants like dust, dirt, sand, and particles from entering the bearing’s internal components. This exclusion minimizes abrasive wear and preserves the integrity of the rolling elements and raceways.

- Moisture and Corrosion Prevention:

Seals and enclosures provide a shield against moisture and water ingress, crucial in preventing corrosion and rust formation on bearing surfaces. Corrosion-resistant seals are particularly valuable in marine and humid environments.

- Chemical and Chemical Vapor Resistance:

Specialized seals and enclosures can offer resistance to chemicals, acids, and corrosive substances that might be present in the operating environment. This protection prevents chemical damage to the bearing’s components.

- Lubrication Retention:

Seals and enclosures help retain the lubricant within the bearing, preventing it from leaking out and ensuring consistent lubrication for smooth operation. This is essential for reducing friction and wear.

- Prevention of Solid Particle Contamination:

Seals and enclosures block solid particles from entering the bearing chamber, reducing the risk of particle-induced wear, surface damage, and premature failure.

- Temperature Regulation:

Some seals and enclosures offer thermal insulation, which helps regulate the operating temperature of the bearing. This can be crucial in applications with extreme temperature variations.

- Enhanced Longevity:

By protecting the bearing from contaminants and adverse environmental conditions, seals and enclosures contribute to the extension of the bearing’s operational life, reducing the need for frequent replacements.

- Sealing Types:

Seals can come in various types, including lip seals, labyrinth seals, and specialized designs. The choice of seal depends on the application’s requirements and the level of protection needed.

- Proper Installation and Maintenance:

Proper installation and regular inspection of seals and enclosures are essential to ensure their effectiveness. Damaged or worn seals should be promptly replaced to maintain protection.

In summary, seals and enclosures serve as a critical defense mechanism for slewing bearings against contaminants, moisture, and harmful substances. They contribute to the bearing’s reliability, performance, and overall longevity in various operating environments.

How does Proper Lubrication Impact the Performance and Longevity of Slewing Bearings?

Proper lubrication plays a crucial role in enhancing the performance and extending the longevity of slewing bearings. Here’s how it impacts these aspects:

- Reduced Friction and Wear:

Lubrication forms a protective layer between the rolling elements and raceways, reducing friction and wear. This minimizes surface contact and prevents metal-to-metal contact, leading to less wear and extended bearing life.

- Heat Dissipation:

Lubrication helps dissipate heat generated during operation. Adequate heat management prevents overheating, which can otherwise lead to premature bearing failure and reduced efficiency.

- Corrosion Protection:

Lubricants with anti-corrosion properties form a barrier that protects bearing surfaces from moisture and environmental contaminants. This is crucial in preventing rust and corrosion, especially in challenging operating environments.

- Sealing Effect:

Lubrication can enhance the sealing effect of bearing seals, preventing the ingress of dust, dirt, and other particles. This maintains the integrity of the bearing’s internal components and reduces the risk of contamination-related failures.

- Noise and Vibration Reduction:

Properly lubricated bearings generate less friction and operate more smoothly, resulting in reduced noise and vibration levels. This is particularly important in applications where noise reduction is essential.

- Improved Efficiency:

Effective lubrication minimizes energy losses due to friction, leading to improved overall efficiency of machinery. This is significant in applications that require high performance and energy savings.

- Prevention of Micro-Movements:

Lubrication helps prevent micro-movements between the rolling elements and raceways, reducing wear caused by repeated impacts and vibrations during operation.

- Maintenance Reduction:

Proper lubrication reduces the need for frequent maintenance and replacement of bearings. This not only saves time and resources but also contributes to increased uptime and reduced operational disruptions.

- Longevity:

By reducing wear, preventing corrosion, and managing heat, proper lubrication significantly extends the lifespan of slewing bearings. This, in turn, contributes to improved equipment reliability and reduced lifecycle costs.

In conclusion, proper lubrication is essential for optimizing the performance, efficiency, and durability of slewing bearings. Regular maintenance and adherence to manufacturer-recommended lubrication intervals ensure that the bearings operate smoothly and consistently over their operational life.

How do Different Types of Slewing Bearings Vary in Terms of Design and Function?

Different types of slewing bearings vary significantly in terms of their design and function, catering to diverse industrial requirements. Some common variations include:

- Single-Row Ball Slewing Bearings: These bearings consist of a single row of balls positioned between two rings. They are compact and suitable for light to moderate axial and radial loads, making them useful in applications like small cranes and excavators.

- Double-Row Ball Slewing Bearings: These bearings have two rows of balls and higher load-carrying capacity compared to single-row types. They find use in applications requiring higher loads and moment resistance, such as larger cranes and construction machinery.

- Three-Row Roller Slewing Bearings: These bearings use cylindrical rollers to handle heavy axial, radial, and moment loads. They are commonly found in heavy-duty applications like harbor cranes and mining equipment.

- Cross Roller Slewing Bearings: These bearings have cylindrical rollers arranged in a crossed pattern between the inner and outer rings. They offer high stiffness and precision, making them suitable for applications like robotic arms and precision machinery.

- Wire Race Slewing Bearings: These innovative bearings use a thin wire race to support the rolling elements. They are lightweight and compact, often used in medical equipment and aerospace applications.

- Ball-And-Roller Combination Slewing Bearings: These hybrid bearings combine ball and roller elements to achieve a balance between load capacity and precision. They find use in various industrial machines and equipment.

- Gearless Slewing Bearings: In some applications, slewing bearings incorporate no gears or teeth. They are used where external gear reduction is present or precise rotation isn’t required.

- Geared Slewing Bearings: These bearings include internal gears or teeth that allow torque transmission between the inner and outer rings. They are essential in applications requiring controlled rotation, such as cranes and wind turbines.

The choice of slewing bearing type depends on factors like load requirements, available space, rotational precision, and the specific industrial application. Understanding the variations helps engineers select the most suitable bearing for optimal performance.

editor by CX 2024-04-12

by

Tags:

Leave a Reply