Product Description

N NU NUP NJ NF Series Engineering Machinery Parts Cylindrical Roller Bearing NU2232EM NU2334EM NU2336EM NU2338EM NU2340EM NU2344EM Roller Bearing NU2348EM

|

Model |

All Standard and Non Standard | ||

| Structure | Single row | ||

| Double rows | |||

| Four rows | |||

| Precision Rating | P0,P6,P5,P4,P2(ABEC1,ABEC3,ABEC5,ABEC7,ABEC9) | ||

| Clearance | C2,C0,C3,C4,C5 | ||

| Viberation Level | V1,V2,V3,V4 | ||

| Material | GCr15/GCr15SiMn | ||

| Application |

Widely used in metallurgy, mining, petroleum, chemical, coal, cement, paper, windpower, heavy machinery, enginnering machinery, port machinery and other industries. |

||

| Delivery time | 1)3-5days for samples | ||

| 2)10-15days | |||

| Payment terms | 1)30%TT in advance,70%balance has to be paid before first shipment. | ||

| 2)100%LC at sight | |||

| 3)Western Union | |||

| 4)Paypal | |||

| 5)other payment terms depend on our discussion | |||

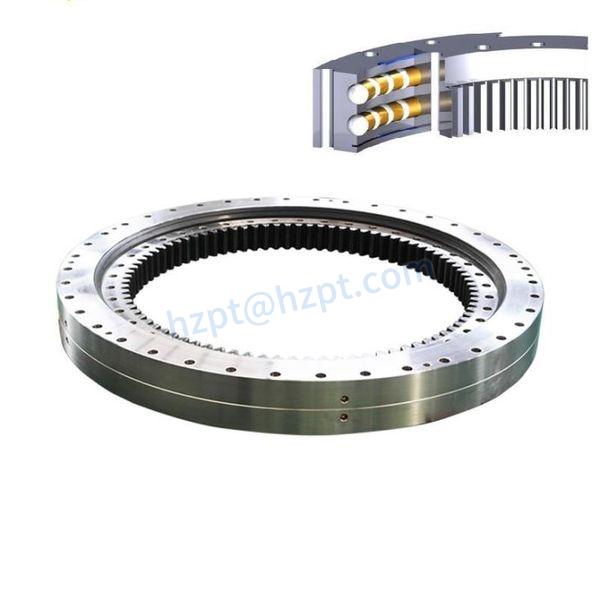

Images

|

Type |

Cylindrical Roller Bearing |

Model |

NN3044-AS-K-M-SP |

|

Brand |

YNR/OEM |

d (mm) |

220mm |

|

Material |

Chrome steel |

D (mm) |

340mm |

|

Type |

Open/Seal |

B (mm) |

90mm |

|

Precision rate |

P0, P6, P5, or as requested |

|

Applicable Industries Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, Farms, Restaurant, Home Use, Retail, Food Shop, Printing Shops,

Company Profile

CONTINUOUS AND STABLE DELIVERY OF PRODUCTS.

Packaging & Shipping

FAQ

Q:Do you accept ODM&OEM orders?

A: Yes, we provide ODM&OEM services to worldwide customers, we are CZPT to customize housings in different styles, and sizes in

different brands, we also customize packaging box as per your requirements.

Q:Do you offer free samples?

A: Yes we offer free small samples to distributors and wholesalers, pls note,if your bearings are bigger,we will send you same

materials/same brands as for sample.however customers should bear freight.

We DO NOT offer free samples to end users.

Q:What’s the MOQ?

A: MOQ is 10pcs for standardized products; for customized products, MOQ should be negotiated in advance.

Q:How long is the lead time?

A: Normally lead time is about 3-7days,if it is customized order ,the lead time will be reconfirmed, about 10-15days.

Q:How to place orders?

A: 1. Email us the model, brand and quantity, consignee information, shipping way and payment terms;

2. Proforma Invoice made and sent to you;

3. Complete Payment after confirming the PI;

4. Confirm Payment and arrange production.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Small and Medium-Sized (60-115mm) |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do Environmental Factors such as Temperature and Exposure to Corrosive Substances Impact Slewing Bearings?

Environmental factors, including temperature variations and exposure to corrosive substances, have a significant impact on the performance and longevity of slewing bearings. Here’s how these factors affect slewing bearings:

- Temperature Extremes:

High Temperatures: Excessive heat can lead to premature bearing failure by affecting the lubrication properties, causing thermal expansion, and accelerating wear. Bearings operating at high temperatures require special lubricants and materials that can withstand thermal stresses.

Low Temperatures: Extremely low temperatures can lead to reduced lubricant viscosity, increasing friction and wear. Bearings operating in cold environments might require low-temperature lubricants and materials that maintain their properties in freezing conditions.

- Corrosive Substances:

Moisture and Water: Exposure to moisture and water can lead to rust, corrosion, and erosion of bearing components. This is particularly relevant in marine environments or applications exposed to frequent wet conditions.

Chemical Exposure: Corrosive chemicals and aggressive substances can deteriorate bearing materials and lubricants, leading to accelerated wear and potential structural damage.

Dust and Particles: Dust, dirt, and particles can infiltrate the bearing, causing abrasive wear and increasing the risk of damage to the rolling elements and raceways.

- Effects on Lubrication:

Temperature extremes and exposure to corrosive substances can compromise the effectiveness of lubrication. High temperatures can degrade lubricants, while corrosive environments can contaminate or dilute lubricants, reducing their protective qualities.

- Material Selection:

When designing slewing bearings for specific environments, choosing appropriate materials is crucial. Stainless steels, specialized coatings, and corrosion-resistant materials are often preferred for applications where corrosion is a concern.

- Sealing Solutions:

Effective sealing solutions are essential to protect slewing bearings from moisture, chemicals, and contaminants. Proper sealing helps maintain lubrication integrity and prevents external substances from entering the bearing.

- Maintenance and Inspection:

Regular maintenance and inspections are critical in environments with temperature fluctuations and corrosive exposure. Prompt removal of contaminants, re-lubrication, and replacement of damaged parts can mitigate the effects of these factors.

- Application-Specific Considerations:

Understanding the environmental conditions of the application is essential for selecting the appropriate slewing bearing type, materials, and maintenance practices. Customized solutions might be necessary for extreme environments.

In summary, temperature variations and exposure to corrosive substances can degrade the performance and durability of slewing bearings. Proper material selection, sealing, lubrication, and maintenance practices are vital for ensuring the bearings’ reliability in challenging environmental conditions.

What are the Signs of a Damaged or Worn-out Slewing Bearing that Requires Replacement?

Identifying the signs of a damaged or worn-out slewing bearing is essential for preventing potential failures and ensuring equipment reliability. Here are common indicators that a slewing bearing may require replacement:

- Unusual Noise:

If you notice grinding, clicking, or any abnormal noises during operation, it could be a sign of wear or misalignment in the slewing bearing.

- Increased Vibration:

Excessive vibration or shaking during rotation could indicate misalignment, damage, or uneven wear in the slewing bearing.

- Irregular Movement:

If the machinery exhibits irregular or jerky movement instead of smooth rotation, it might be due to a damaged slewing bearing.

- Uneven Load Distribution:

Uneven distribution of loads can lead to accelerated wear on specific sections of the bearing, causing premature failure.

- Abnormal Heat Generation:

If the slewing bearing becomes excessively hot during operation, it may suggest friction, misalignment, or lack of proper lubrication.

- Excessive Play or Clearance:

Too much axial or radial play in the bearing can indicate wear, misalignment, or component fatigue, requiring inspection and potential replacement.

- Leakage of Lubricant:

If lubricant leaks from the bearing or seals, it may signify damage to the sealing mechanism or an internal issue that needs attention.

- Visible Wear or Damage:

Inspect the bearing for visible signs of wear, corrosion, pitting, or other forms of damage. Cracks, dents, or deformation are clear indicators of potential problems.

- Reduced Performance:

If the machinery’s performance deteriorates, such as decreased rotation speed, reduced load capacity, or increased power consumption, it could be due to a failing slewing bearing.

- Increased Maintenance Frequency:

If you find yourself needing to perform more frequent maintenance or repairs on the bearing, it might indicate that the bearing is nearing the end of its service life.

- Manufacturer’s Service Life:

Consult the manufacturer’s guidelines for the expected service life of the slewing bearing. If the bearing is approaching this limit, it’s advisable to consider replacement.

If any of these signs are observed, it’s important to consult with experts and consider replacing the slewing bearing to prevent further damage and ensure the safe and efficient operation of machinery.

What are the Main Applications of Slewing Bearings?

Slewing bearings find wide applications across various industries due to their ability to handle complex loads and facilitate rotational movement. Some of the main applications of slewing bearings include:

- Construction Machinery: Slewing bearings are essential components in construction equipment such as excavators, cranes, concrete pumps, and drilling rigs. They enable smooth rotation and movement, supporting heavy loads and dynamic forces.

- Wind Turbines: In wind energy systems, slewing bearings are used to orient the rotor blades and nacelle to capture maximum wind energy. Their durability and load-bearing capacity make them crucial for efficient wind turbine operation.

- Mining Equipment: Slewing bearings are used in mining machinery like stacker-reclaimers and conveyor systems. They enable the movement of large loads, contributing to efficient material handling and processing.

- Marine Applications: Slewing bearings are employed in ship cranes, davits, and other marine equipment. They assist in cargo handling, ship maintenance, and various onboard operations.

- Aerial Work Platforms: Slewing bearings are integral to aerial platforms and access equipment. They enable controlled and safe movement for workers at elevated heights.

- Robotics and Automation: Slewing bearings play a role in industrial robots and automation systems. They facilitate precise and controlled rotational movement in manufacturing processes.

- Medical Equipment: Some medical imaging equipment, such as CT scanners and MRI machines, use slewing bearings for rotational movement, contributing to accurate diagnostics.

- Defence and Aerospace: Slewing bearings are employed in defense equipment like radar systems and missile launchers, as well as in aerospace applications like aircraft landing gear.

These are just a few examples of the many applications of slewing bearings across different industries. Their ability to handle diverse loads and rotational movements makes them versatile components in various machinery and equipment.

editor by CX 2024-04-22

by

Tags:

Leave a Reply