Product Description

Product Description

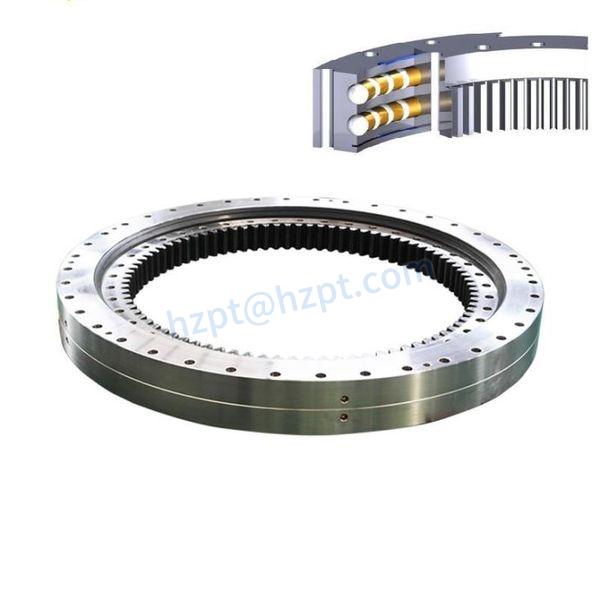

Products details as:

Cross roller bearings

Competitive price

Hot sales

Super popular

High quality

High precision

High speed

Durable

Long life

Low noise

Other Models of Roller

|

item |

value |

|

Type |

Slewing Bearing |

|

Applicable Industries |

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Retail, Other |

|

Feature |

Four Point Contact |

|

Gear Options |

Internal Gear Only |

|

Seals Type |

seal |

|

Package |

Wooden Box |

|

Warranty |

12 Months |

|

Structure |

Single Row Four Contact Ball |

|

Certificate |

ISO9001:2008 |

|

Precision |

P2 P4 P5 P6 P0 |

|

Quality |

High-Quality |

|

Model |

Inner Dia. |

Outer Dia. |

Pitch Dia. |

Weight |

|

d(mm) |

D(mm) |

Dpw(mm) |

m(Kg) |

|

|

RU42 |

20 |

70 |

41.5 |

0.29 |

|

RU66 |

35 |

95 |

66 |

0.62 |

|

RU85 |

55 |

120 |

85 |

1 |

|

RU124(G) |

80 |

165 |

124 |

2.6 |

|

RU124X |

80 |

165 |

124 |

2.6 |

|

RU148(G) |

90 |

210 |

147.5 |

4.9 |

|

RU148X |

90 |

210 |

147.5 |

4.9 |

|

RU178(G) |

115 |

240 |

178 |

6.8 |

|

RU178X |

115 |

240 |

178 |

6.8 |

|

RU228(G) |

160 |

295 |

227.5 |

11.4 |

|

RU228X |

160 |

295 |

227.5 |

11.4 |

|

RU297(G) |

210 |

380 |

297.3 |

21.3 |

|

RU297X |

210 |

380 |

297.3 |

21.3 |

|

RU445(G) |

350 |

540 |

445.4 |

35.4 |

|

RU445X |

350 |

540 |

445.4 |

35.4 |

Application Scenarios

Related products

product-list-1.html

Company Profile

HangZhou Terry Machinery Co.Ltd is a leading supplier of bearings, Linear motion system for CNC , Ball transfer Unit and transmission component .the growing industrial and Favorable policy of HangZhou benefit the development of Terry Machinery .Our products are utilized in industrial, motorcycle, vehicle and Automation applications. Now we are exporting to 46 countries. including USA, GBR , Germany , Spain, Poland ,Turkey ect .The Goal of Terry Machinery to provide out customers with widest range of products at competitive prices, backed with the best Service.OUR ADVANTAGE Products Our major products & Supplied:Meet all the international standards and ISO9001 -TS1694 Certificate Big volume in Stock, No MOQ required Personnel Our salespersons are well trained to accommodate your requests and speak English for your conveniences.Our technicians and engineers Experience in the Industry area exceeds 23 years Service &Quality control ,We supply detailed drawings and offer when ever necessary,We help all customers promote and improve their sales.We inspect every piece of products by ourselves before delivery.

Packaging & Shipping

FAQ

Customer Praise

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 0 |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do Environmental Factors such as Temperature and Exposure to Corrosive Substances Impact Slewing Bearings?

Environmental factors, including temperature variations and exposure to corrosive substances, have a significant impact on the performance and longevity of slewing bearings. Here’s how these factors affect slewing bearings:

- Temperature Extremes:

High Temperatures: Excessive heat can lead to premature bearing failure by affecting the lubrication properties, causing thermal expansion, and accelerating wear. Bearings operating at high temperatures require special lubricants and materials that can withstand thermal stresses.

Low Temperatures: Extremely low temperatures can lead to reduced lubricant viscosity, increasing friction and wear. Bearings operating in cold environments might require low-temperature lubricants and materials that maintain their properties in freezing conditions.

- Corrosive Substances:

Moisture and Water: Exposure to moisture and water can lead to rust, corrosion, and erosion of bearing components. This is particularly relevant in marine environments or applications exposed to frequent wet conditions.

Chemical Exposure: Corrosive chemicals and aggressive substances can deteriorate bearing materials and lubricants, leading to accelerated wear and potential structural damage.

Dust and Particles: Dust, dirt, and particles can infiltrate the bearing, causing abrasive wear and increasing the risk of damage to the rolling elements and raceways.

- Effects on Lubrication:

Temperature extremes and exposure to corrosive substances can compromise the effectiveness of lubrication. High temperatures can degrade lubricants, while corrosive environments can contaminate or dilute lubricants, reducing their protective qualities.

- Material Selection:

When designing slewing bearings for specific environments, choosing appropriate materials is crucial. Stainless steels, specialized coatings, and corrosion-resistant materials are often preferred for applications where corrosion is a concern.

- Sealing Solutions:

Effective sealing solutions are essential to protect slewing bearings from moisture, chemicals, and contaminants. Proper sealing helps maintain lubrication integrity and prevents external substances from entering the bearing.

- Maintenance and Inspection:

Regular maintenance and inspections are critical in environments with temperature fluctuations and corrosive exposure. Prompt removal of contaminants, re-lubrication, and replacement of damaged parts can mitigate the effects of these factors.

- Application-Specific Considerations:

Understanding the environmental conditions of the application is essential for selecting the appropriate slewing bearing type, materials, and maintenance practices. Customized solutions might be necessary for extreme environments.

In summary, temperature variations and exposure to corrosive substances can degrade the performance and durability of slewing bearings. Proper material selection, sealing, lubrication, and maintenance practices are vital for ensuring the bearings’ reliability in challenging environmental conditions.

What are the Common Maintenance Practices for Ensuring the Durability of Slewing Bearings?

Maintaining slewing bearings is crucial for ensuring their longevity and optimal performance. Here are some common maintenance practices to enhance the durability of slewing bearings:

- Regular Inspection:

Perform routine visual inspections to check for signs of wear, corrosion, and damage. Inspect seals, lubrication levels, and any unusual noises or vibrations during operation.

- Lubrication:

Follow the manufacturer’s guidelines for lubrication intervals and use appropriate lubricants. Lubricate the bearings to ensure smooth operation, reduce friction, and prevent wear.

- Seal Maintenance:

Inspect and maintain seals to prevent the ingress of contaminants such as dust, dirt, and moisture. Damaged or worn seals should be replaced promptly.

- Cleaning:

Regularly clean the bearing and its surrounding area to remove dirt, debris, and contaminants that could affect performance. Keep the bearing environment as clean as possible.

- Environmental Protection:

If the bearings are exposed to harsh conditions, consider using protective covers or shields to prevent direct exposure to elements like water, chemicals, and abrasive materials.

- Alignment and Mounting:

Ensure proper alignment during installation to prevent unnecessary stress on the bearing. Accurate mounting reduces the risk of misalignment-related failures.

- Torque Monitoring:

If the bearing has gears, regularly monitor and maintain the torque levels to prevent overloading and premature wear.

- Load Distribution:

Operate the machinery within the specified load limits to avoid overloading the bearing, which can lead to fatigue and failure.

- Replacement of Worn Components:

If any components, such as seals or lubrication fittings, show signs of wear, replace them promptly to maintain the integrity of the bearing system.

- Documentation:

Maintain records of maintenance activities, including lubrication schedules, inspections, and any repairs or replacements. This documentation helps track the bearing’s history and aids in decision-making.

- Training:

Ensure that maintenance personnel are adequately trained to carry out proper inspection, lubrication, and maintenance procedures.

By implementing these maintenance practices, you can maximize the service life of slewing bearings, minimize downtime, and maintain consistent machinery performance.

Can you Explain the Differences Between Single-Row and Double-Row Slewing Bearings?

Single-row and double-row slewing bearings are two common configurations with distinct characteristics. Here are the key differences between them:

- Design:

A single-row slewing bearing consists of one row of rolling elements positioned between the inner and outer rings. In contrast, a double-row slewing bearing has two rows of rolling elements.

- Load-Carrying Capacity:

Double-row slewing bearings generally have a higher load-carrying capacity compared to single-row bearings. The presence of two rows of rolling elements enables them to handle heavier axial, radial, and moment loads.

- Stiffness:

Double-row bearings offer higher stiffness due to the additional row of rolling elements. This stiffness can be advantageous in applications where precise positioning and resistance to deflection are crucial.

- Compactness:

Single-row slewing bearings are typically more compact and have a smaller profile compared to double-row bearings. This compact design can be advantageous in applications with limited space.

- Cost:

Single-row slewing bearings are generally more cost-effective compared to double-row bearings. The increased complexity and higher load capacity of double-row bearings can result in higher manufacturing costs.

- Applications:

Single-row slewing bearings are suitable for applications with moderate loads and rotational requirements, where compactness is important. Examples include small cranes, excavators, and material handling equipment. Double-row slewing bearings are often used in larger and heavier machinery, such as construction equipment, wind turbines, and heavy-duty cranes.

- Performance Trade-offs:

While double-row bearings offer higher load capacity and stiffness, they may also introduce higher friction and slightly reduced rotational efficiency compared to single-row bearings due to the presence of additional rolling elements.

In summary, the choice between single-row and double-row slewing bearings depends on factors like load requirements, available space, and desired stiffness. Each configuration has its own advantages and trade-offs, allowing engineers to tailor their selection to the specific needs of the application.

editor by CX 2024-05-08

Leave a Reply