Product Description

Product Description

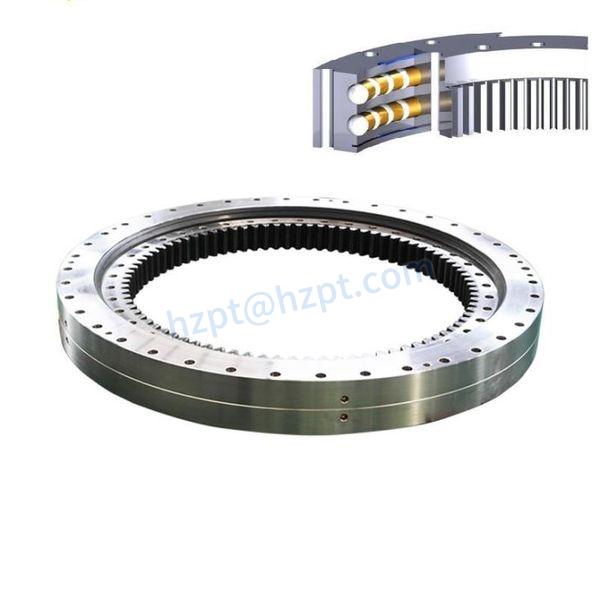

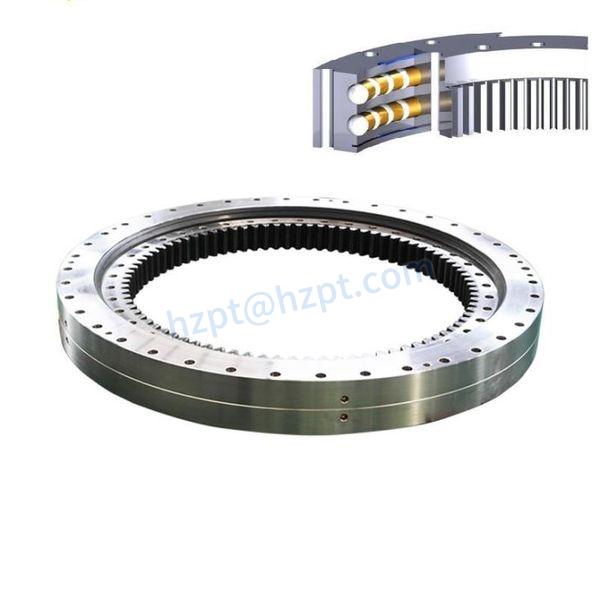

Tower crane bearings is the main parts to help the tower crane do slewing working. Our tower crane slewing bearing is made of 42-42CrMo, 40-40Cr or 50-50Mn.

Ruding Steel can produce both standard and non-standard tower crane bearing, with sizes ranging from 60mm-4000mm.

Specifications:

|

Applicable Industries |

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Farms, Home Use, Food Shop, Construction works , Energy & |

|

Brand Name |

HELIN |

|

Model Number |

571.40.1250 |

|

Feature |

Four Point Contact |

|

Gear Options |

External Gear |

|

Place of Origin |

ZheJiang , China |

|

Bearing type |

Single Row Four Point |

|

Hardness |

55-62HRC |

|

Application |

Crane, Excavator, Tower crane, AGV |

|

Material |

50Mn/42CrMo |

|

Packing |

Wooden Box |

|

Certificate |

ISO9001:2015 |

We can design tower crane bearing as customers requirements and specifications.

Manufacturing Process:

Forging ring body material — Rough Lathing — Raceway heat treatment — Drilling — Teeth cutting — Teeth heat treatment — Ball hardness inspection — Assembling — Finall inspection — Packaging

Packaging & Shipping

Contact us

Please contact us for more information and quotations.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Vacuum, Antimagnetic, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Non-Seal |

| Samples: |

US$ 1000/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How do Environmental Factors such as Temperature and Exposure to Corrosive Substances Impact Slewing Bearings?

Environmental factors, including temperature variations and exposure to corrosive substances, have a significant impact on the performance and longevity of slewing bearings. Here’s how these factors affect slewing bearings:

- Temperature Extremes:

High Temperatures: Excessive heat can lead to premature bearing failure by affecting the lubrication properties, causing thermal expansion, and accelerating wear. Bearings operating at high temperatures require special lubricants and materials that can withstand thermal stresses.

Low Temperatures: Extremely low temperatures can lead to reduced lubricant viscosity, increasing friction and wear. Bearings operating in cold environments might require low-temperature lubricants and materials that maintain their properties in freezing conditions.

- Corrosive Substances:

Moisture and Water: Exposure to moisture and water can lead to rust, corrosion, and erosion of bearing components. This is particularly relevant in marine environments or applications exposed to frequent wet conditions.

Chemical Exposure: Corrosive chemicals and aggressive substances can deteriorate bearing materials and lubricants, leading to accelerated wear and potential structural damage.

Dust and Particles: Dust, dirt, and particles can infiltrate the bearing, causing abrasive wear and increasing the risk of damage to the rolling elements and raceways.

- Effects on Lubrication:

Temperature extremes and exposure to corrosive substances can compromise the effectiveness of lubrication. High temperatures can degrade lubricants, while corrosive environments can contaminate or dilute lubricants, reducing their protective qualities.

- Material Selection:

When designing slewing bearings for specific environments, choosing appropriate materials is crucial. Stainless steels, specialized coatings, and corrosion-resistant materials are often preferred for applications where corrosion is a concern.

- Sealing Solutions:

Effective sealing solutions are essential to protect slewing bearings from moisture, chemicals, and contaminants. Proper sealing helps maintain lubrication integrity and prevents external substances from entering the bearing.

- Maintenance and Inspection:

Regular maintenance and inspections are critical in environments with temperature fluctuations and corrosive exposure. Prompt removal of contaminants, re-lubrication, and replacement of damaged parts can mitigate the effects of these factors.

- Application-Specific Considerations:

Understanding the environmental conditions of the application is essential for selecting the appropriate slewing bearing type, materials, and maintenance practices. Customized solutions might be necessary for extreme environments.

In summary, temperature variations and exposure to corrosive substances can degrade the performance and durability of slewing bearings. Proper material selection, sealing, lubrication, and maintenance practices are vital for ensuring the bearings’ reliability in challenging environmental conditions.

Are there any Specific Safety Precautions to Take When Working with Slewing Bearings?

Working with slewing bearings involves certain safety considerations to prevent accidents and ensure the well-being of personnel. Here are some specific safety precautions to take:

- Training and Knowledge:

Ensure that personnel working with slewing bearings are properly trained and have a clear understanding of the equipment, procedures, and safety protocols.

- Protective Equipment:

Use appropriate personal protective equipment (PPE), including gloves, safety goggles, and hearing protection, to safeguard against potential hazards.

- Lockout/Tagout:

Follow lockout/tagout procedures when performing maintenance or repairs. Locking out equipment prevents unexpected activation and potential hazards.

- Machine Shutdown:

Before working on machinery containing slewing bearings, ensure that the equipment is properly shut down, power sources are disconnected, and any stored energy is released.

- Proper Tools:

Use suitable tools and equipment for maintenance and assembly to prevent accidents and ensure accurate work.

- Weight Handling:

If handling heavy slewing bearing components, use appropriate lifting equipment and techniques to avoid strain or injury.

- Secure Work Area:

Ensure that the work area is clean, organized, and free from obstacles. This reduces the risk of tripping hazards and improves overall safety.

- Work with a Partner:

Whenever possible, perform tasks involving slewing bearings with a partner. Having someone nearby can provide assistance in case of emergencies.

- Safe Access:

Ensure safe access to the work area, including the use of stable platforms or ladders, to prevent falls or slips.

- Warning Signs:

Use proper warning signs and labels to alert others about ongoing maintenance or potential hazards related to slewing bearings.

- Manufacturer Guidelines:

Adhere to the manufacturer’s recommendations for maintenance, lubrication, and safety practices specific to the slewing bearings being worked on.

- Emergency Procedures:

Have clear emergency procedures in place and communicate them to all personnel. Know the location of emergency equipment and exits.

By following these safety precautions, you can minimize risks associated with working on slewing bearings and create a safer environment for maintenance personnel.

What Factors Should Be Considered When Selecting a Slewing Bearing for a Specific Application?

Selecting the right slewing bearing for a specific application requires careful consideration of various factors to ensure optimal performance and longevity. Some crucial factors to take into account include:

- Load Requirements: Determine the axial, radial, and moment loads that the slewing bearing will need to support. Choose a bearing with an appropriate load-carrying capacity for the application.

- Space Limitations: Consider the available installation space, both in terms of diameter and height. Choose a slewing bearing that fits within the allocated space without compromising functionality.

- Rotational Speed: Determine the required rotational speed of the bearing. Higher rotational speeds may require bearings with advanced designs and materials to manage heat and wear.

- Environmental Conditions: Assess the operating environment for factors like temperature, humidity, dust, and corrosive substances. Select a bearing with suitable seals and coatings to withstand these conditions.

- Accuracy and Precision: For applications requiring precise positioning, such as robotics or industrial machinery, choose a bearing that offers the necessary level of accuracy in rotation.

- Mounting and Assembly: Consider the ease of installation and any special mounting requirements. Some bearings come with integrated mounting features, simplifying the assembly process.

- Lubrication and Maintenance: Evaluate the lubrication needs of the bearing. Some bearings require periodic maintenance, while others are designed for long-term lubrication.

- Expected Lifespan: Determine the desired lifespan of the bearing in relation to the application’s operational requirements. High-quality bearings with robust construction may offer longer service life.

- Cost-Benefit Analysis: Balance the initial investment with long-term benefits. Consider factors like maintenance costs, downtime, and overall equipment performance.

- Industry Standards: Ensure that the selected slewing bearing complies with relevant industry standards and regulations for safety and quality.

Ultimately, the selection process involves matching the unique requirements of the application with the capabilities of the slewing bearing. Consulting with bearing manufacturers and experts can provide valuable insights to make an informed decision.

editor by CX 2024-05-09

Leave a Reply